Our patented technology is called Direct Carbon Immobilization or DCI™.

DCI™ is a thermochemical separation technology which is designed to process mixed waste and biomass to produce syngas and cleaned solids.

DCI™ is gasification, a process which is in operation for over 100 years like in coke making, of solid waste in a relatively slow and stable process. The slow vertical speed within the reactor limits mechanical abrasion and guarantees complete conversion of hydro carbons in gas and solid carbon.

The gas is heated up further to ensure decomposition of complex hydrocarbons like PAH’s, dioxins and PFAS and results in the production of syngas.

Agglomeration of the solids is little to none due to avoiding melting temperatures of slags.

All this is done in the same reactor.

To convey the maturity of our innovation we refer to the Technology Readiness Level system, which has steps 1 to 9.

TRL 1 and 2 were covered by our literature study and patent.

TRL 3 was covered during laboratory testing.

TRL 4 & 5 were reached in our pilot called Lab Scale Reactor for DCI™ with a capacity of 4 kg/h

TRL 6 will be reached in our DCI™ with an expected capacity of 6 kg/h.

TRL 7 & 8 will be reached in a demonstration plant which will have an expected capacity of 50-100 kg/h and is part of a 24/7 operating facility.

TRL 9 will be reached in a demonstration plant which will have an expected capacity of 1000 kg/h and is part of a 24/7 operating facility.

2022 - Q3

Our IP became established worldwide after our first patent was issued on July 14th 2022. Following this milestone, we reached Technology Readiness Levels (TRL) 1 and 2.

2022 - Q4

We demonstrated proof of principle that gasification is possible in refractory materials, reached TRL 3, and distributed a detailed report to our sponsors.

2023 – Q1

We commissioned the LSR 80 and began operations with the dedicated DCI furnace. We reached TRL 4 and distributed a report to our sponsors.

2023 – Q2

We began small sample testing in the DCI furnace with the start of micro container tests to repeat the the P.O.P in the LSR 80.

2023 – Q3

We conducted the first oxygen injections in the DCI furnace, reached TRL 5, and distributed a report to our sponsors.

2024 – Q1

The first scale step which increased the shaft diameter from 80 mm to 100 mm to enhance flow volume. Additionally, the initial trials with a new gas cleaning system were started.

2024 – Q2

The commissioning of the LSR 100 brings several advancements, including newly retrievable activated carbon which adds product value from the DCI. Additionally, the first run of a printed circuit board has been initiated to begin complex waste separation. Other developments include the initial processing of waste wood class A and B, and the start of automating the output of the solid products from the DCI.

2024 – Q3

Reaching TRL 6 and a report will be distributed to sponsors.

2025

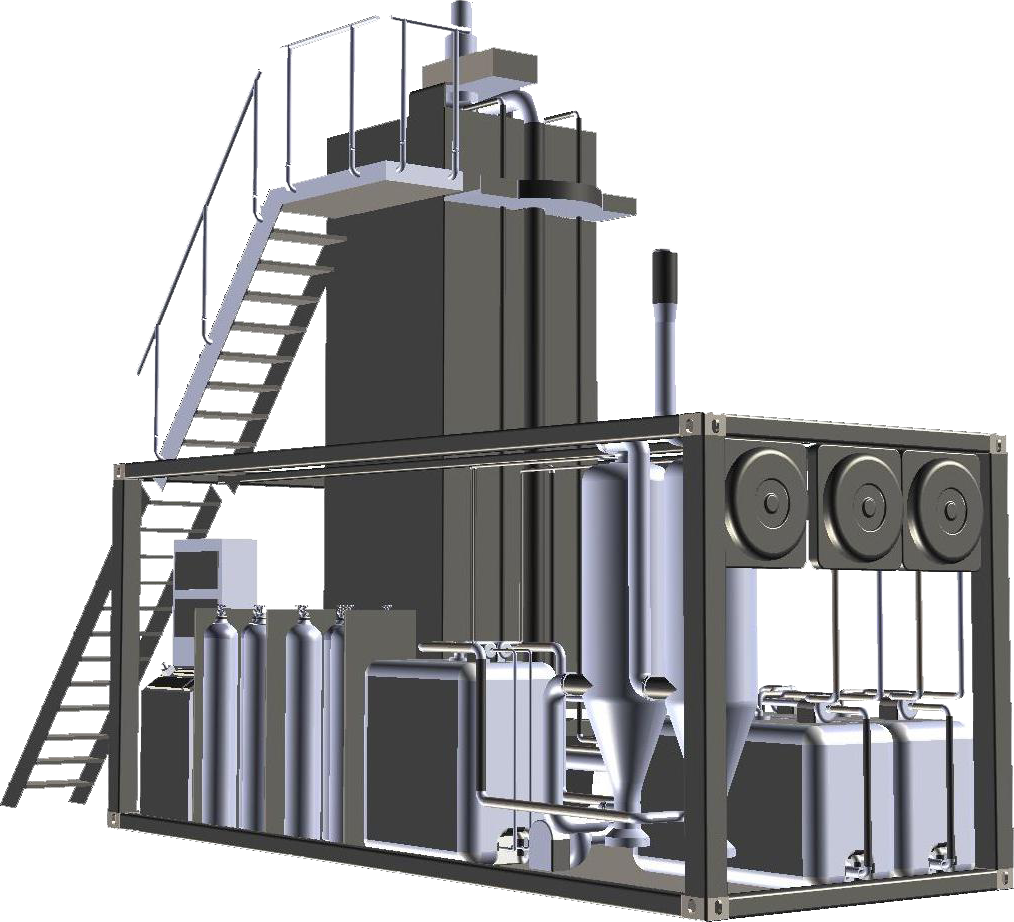

We will begin operations for the Mobile-DCI, which will be the first industrial-sized DCI furnace. TRL 7 and 8 will be reached and a report will be distributed to sponsors.

2026

We will start operating DCI facility to replace natural gas and produce activated carbon. TRL 9 will be reached and a report will be distributed to sponsors.

2027

We will being operating DCI facility to produce methanol and liberated metals and minerals.